EOM power and lighting project for an office center

Our The design company has developed the working documentation of the PD of power and lighting EOM for the office center .

DESIGN OF ELECTRICAL SUPPLY TO THE EOM

The electrical installation of the MCC building shall have high levels of safety and reliability, meet the requirements of fire safety, take into account the possibility of expansion during operation and ease of operational maintenance. All equipment of the system from the main distribution boards (MDB) to the floor boards should be made by the same manufacturer. The imported electrical power equipment and electrical materials used shall be certified and recommended for use in accordance with the regulations and rules applicable in the Russian Federation. Equipment suppliers must have representative offices and service centers in Moscow. Electrical equipment used in the EOM section shall comply with GOST R requirements for use in the Russian Federation and shall have conformance, fire and hygienic certificates.

Description of the object of design of EM

-

Power supply.

According to the degree of reliability of power supply of consumers of CDC refers to the II category, except for consumers of fire-fighting devices (fire pumps, devices air overpressure and smoke removal, installations fire fighting, fire alarm and warning people about the fire), security alarm and building security systems, telecommunications equipment and server rooms, special rooms (control rooms, etc.), which belong to the I category.

The power supply of the MCC is planned to be carried out from the built in (attached) in the building distribution transformer station (RTS) at 10 kV (see Sections EIS 1.1 and EIS1.2). Installed capacity of electrical consumers GDC is 7294 kW, and a single power including compensation and mismatch maximum 4451.6 kW/4637 kVA. The calculation was made on the basis of the initial data on the consumption from the Customer and assignments from the technological sections of the project (ventilation, heating, water supply, plumbing, smoke removal, refrigeration equipment, elevators, etc.).

The given calculations have been performed in accordance with the requirements of SP 31-110-2003. The preliminary calculation of electric loads (summer and winter maximum) for the complex is given in the tables

-

Power equipment.

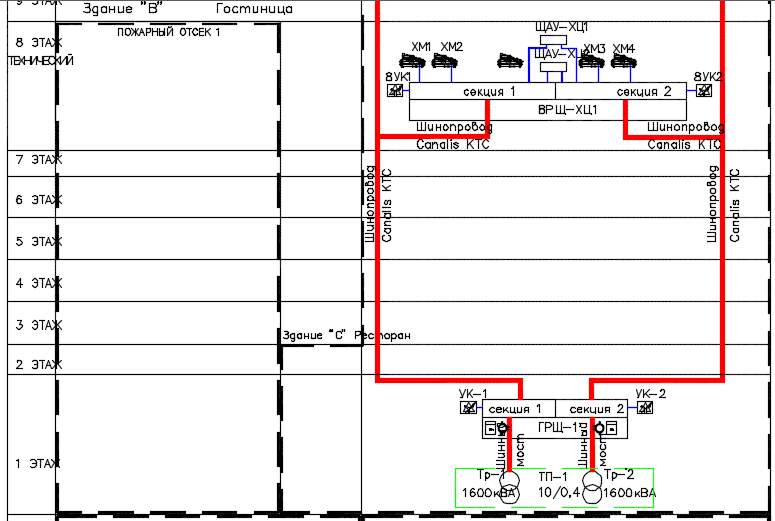

The power supply of the MCC building is carried out from three built-in two transformer substations (TS) building voltage 10/0,4 kV. The design of transformer substations and cable or busbar connection of the transformer substation with the main switchboard is not included in the scope of this volume and is discussed in detail in EIS Volume 1.2. The description of the internal power supply system starts with the cells of the Main Distribution Switchboards 0.4 kV (MCB) of the building. According to the degree of power supply reliability, the electrical installation of the MCC building belongs, in general, to the II category of power supply. The grounding system is of TN-C-S type from the transformer substation to the main switchboard. Separation of PEN conductor into PE and N conductors takes place directly in the main switchboard. Further along the building, the grounding system is of TN-S type. Electricity distribution to the consumers is performed at voltage ~380/220 V five-wire (three wire) system 3 (1) phase, N, PE, using the fifth (third) conductor PE as a grounding. Reactive power compensation is provided in the main distribution boards. Main distribution boards (MDBs) are located in the rooms adjacent to the TP on the 1st floor of the MCC. The loads of each fire compartment of the MCC building shall be powered from the main distribution switchboard through the fire protection equipment panels (FPU-OP). Equipment FPU-FPU located in the appropriate fire compartment in the room electrical switchboard. In addition to Category II consumers, there are Category I and III consumers of reliability of power supply to consumers in the building of the MCC.

Consumers of the first category of reliability of power supply of MCC include the following consumers:

- fire alarm systems;

- fire extinguishing systems;

- smoke exhaust and air-supply systems;

- fire automation systems;

- security systems (access control, video surveillance, security alarms);

- automation and dispatching systems;

- elevators for transportation of firefighting units;

- emergency (evacuation and security lighting) and duty lighting.

Consumers I category of reliability to connect through ATS units (automatic reserve input), which must have two mutually redundant power supply.

Power supply to consumers of I category that do not tolerate power outages shall be provided by group (local) uninterruptible power supplies (UPS). A centralized UPS is not provided. Location of local UPS are indicated in the relevant sections of the project.

-

Main switchboards.

Shields GRShch are two-sectional, equipped with ATS (automatic transfer switch) on the sectional circuit breakers. Each transformer in nominal mode is loaded approximately at 50% of capacity, when the 0.4 kV main circuit breaker is triggered (shutdown), the sectional circuit breaker will automatically turn on. In emergency mode, each of the power transformers provides power to all consumers connected to both sections of the main switchboard. In the emergency mode, the load of each transformer does not exceed 110% of the transformer rated capacity. Sectionalization of RU-0,4 kV (main distribution switchboard of GRSh) - on the sectional switch with AVR. Main switchgear panels are equipped with Prisma-P type cabinets (Schneider Electric production) or similar cabinets according to technical characteristics.Principal diagrams of main switchgears are given in this volume on drawings IOS1.3 sheet 4-6. Main switchboard panels are equipped with instrumentation that controls current and voltage as well as frequency, active and reactive power. The position of all switching devices shall be displayed on all panels of the main switchboard. Circuit breakers on outgoing lines are equipped with independent trip units and additional contacts to provide remote control and signaling. All circuit breakers are equipped with overcurrent protection units. Main switchboard is located in a separate room on the 1st floor (height 0.000). Layout of equipment GRShch are given in this volume in the drawing IOS1.3 sheet 15. The performance of inputs from transformers to RU-0, 4kV provided tires CANALIS KTA-32 (production Schneider Electric) for rated currents 3200 A and protection degree IP55 or similar equipment. Provided for measurement of voltage in each section of 0,4 kV RU (Main switchboard), and measurement of current on all input and output lines of 0,4 kV RU. Cables and bus ducts are inserted into the main switchboard cabinets from above. Each cabinet has 20% free space reserve. The scheme of power distribution - three-phase five-wire (TN-S), voltage 380/220 V with a protective conductor (PE). The project provides reactive power compensation up to a power factor of 0.96, through automatically regulated batteries of static capacitors installed in the control room. And the capacitors are also provided in the cooling center panel.

-

Input and distribution boards.

For each fire compartment (4 fire compartments in the building) there is a separate room - the electrical switchboard of the fire compartment. The installation of input and output switchgear (IED) for the load of the given fire compartment is provided in these switchgear cabinets. Structurally, the switchboards are made similar to the GRS cabinets, with an upper cable entry.

Apart from the rooms with switchboards in all the floors, there are separate floor electric switchboards, in which distribution and lighting panels are installed for the given floor within the fire compartment.

The power supply network is made according to the trunking scheme with the use of:

- bus ducts - for power supply to the office part;

- bus ducts - for power supply to the hotel load;

- bus ducts - for power supply to the refrigeration center;

- cable lines - for other consumers.

From the main switchboard to the switchboard of each fire compartment by two mutually redundant cable lines. From shields switchgear to equipment related to the given fire compartment is performed cable lines. The circuit diagrams of these switchgears are shown on the IOS1.3 Sheets 10 to 14. The power lines that pass through the fire compartments are laid in ducts, shafts, and fire-resistant ducts with fire resistance rating at least 2.5 hours (REI 150). The distribution inside the fire compartment is done with copper cables with halogen-free, flame-retardant polymer insulation for the lighting and outlets, mineral-insulated cables with copper conductors for power lines and control and monitoring lines for power consumers of the fire-fighting systems. Mutually redundant cable lines are laid on different routes or in different trays. Passage of cables through ceilings, walls are made in metal pipes and openings. After laying the cables in the holes in the pipes and openings are filled with easily penetrable fire protection material with the required fire resistance rating. Electricity distribution in the leased premises is carried out from individual switchboards installed by tenants in agreement with the operations department. Floor distribution boards are installed in the electric switchboards on each floor of the building, local distribution boards are installed directly at the consumers.

-

Electricity metering.

Commercial metering of power is designed in accordance with the requirements of the specifications and is performed on the balance line between the Moscow Unified Electricity Distribution Network Company and the subscriber. The balance line is located at the input terminals of the circuit breakers in each main distribution switchboard of all substations. Metering cabinets in which electricity meters are installed are provided in the distribution and control rooms. Metering devices approved by the Russian Gosstandart and registered in the State Register of Measuring Devices are used for electric power metering. The type of meters is Alfa A1800 A18-05-RL-P2-GB1, accuracy grade 05. Metering cabinets are locked and equipped with sealing devices for meters. In accordance with the requirements of clause. 1.5.17 PUE it is allowed to use current transformers with an overestimated transformation ratio if at maximum load of the connection current in the secondary winding of the current transformer does not exceed 40% of the rated current of the meter, and at minimum - not less than 5%. The current flowing through the current transformer is determined by the formula:

where:

Ipc. - design current, A;

Ktr. - current transformer transformation ratio.

The data for selection are given in the table:

|

№№ |

Name of place of installation of transformer |

Max. |

Min. |

Type |

Ratio of transformation. |

Max. |

Min. |

|

1 |

MAIN SWITCHBOARD-1 (Input 1) |

2300 |

416 |

SE TI 2500 /5 |

500 |

4,6 |

0,83 |

|

2 |

MAIN SWITCHBOARD-1 (Inlet 2) |

2300 |

318 |

SE TI 2500 /5 |

500 |

4,6 |

0,64 |

|

3 |

MAIN SWITCHBOARD-2 (Input 1) |

2074 |

41 8 |

SE TI 2500 /5 |

500 |

4,2 |

0,84 |

|

4 |

MAIN SWITCHBOARD-2 (Inlet 2) |

2074 |

467 |

SE TI 2500 /5 |

500 |

4,2 |

0,93 |

|

5 |

MAIN SWITCHBOARD-3 (Input 1) |

2074 |

41 8 |

SE TI 2500 /5 |

500 |

4,2 |

0,84 |

|

6 |

MAIN SWITCHBOARD-3 (Entry 2) |

2074 |

467 |

SE TI 2500 /5 |

500 |

4,2 |

0,93 |

The metering circuits of electricity meters are connected to current transformers. Current transformers (CTs) are of TI (Schneider Electric) type with accuracy class - 0,25 S. Outputs of CT secondary windings are closed from unauthorized access and provide the possibility of sealing. In accordance with the requirements of par. 1.5.17 PUE it is allowed to use current transformers with an overestimated transformation ratio, if at maximum load of the connection the current in the secondary winding of the current transformer is not more than 40% of the rated current of the meter, and at minimum - not less than 5%. In front of the meter directly connected to the network, at a distance of not more than 10 m along the length of the wiring for safe replacement of the meter is a fuse that allows you to remove the voltage from all phases connected to the meter. Ammeters and voltmeters are installed on the inputs to the main switchboard 0,4 kV to control current and voltage in each phase, taking into account the requirements of Chapter 1.5 of PUE. In accordance with Chapter 1.5 of the PUE, test pads (terminal blocks) shall be installed under the billing meters. Technical (control) electricity metering is provided for restaurants, commercial premises, hotels, and parking lots. Technical metering shall be performed by three-phase electronic meters installed in separate metering cabinets in the electrical switchboard rooms located on all floors of the building. Consumer voltage - ~380/220 V, 50 Hz, the quality of electricity consumers meet the requirements of GOST 13109-97. The requirements to the IASUE project are defined by technical conditions, issued by Moscow City Electric Company OJSC.

The dispatching project provides for centralized electricity metering with meter readings displayed on the dispatcher's display. The building also provides for an automated process control system. The ACMS system of the building complex provides on-line control of electrical equipment of the power supply system, to account for electrical consumption, to monitor the parameters of the power grid and equipment. The objects of automation and dispatching are GRES and VRU.

Automation scheme shall provide:

remote control of the state of automatic machines of input, sectional switch AVR;

remote and local control of outgoing lines (position alarm, emergency shutdown and measurement of load currents);

remote sensing of the main switchboard inputs.

All the above-mentioned circuit breakers shall have position and emergency shutdown signaling, and the pull-out circuit breakers shall additionally have "pumped in", "pumped out", "test", "ready for startup" signaling. ATS must have additional signaling of operation. For more details on the ATS system, see the APIOS kit.

-

Secondary distribution.

According to the degree of reliability of electricity supply this building is classified as II category, except for electric consumers of the fire-prevention devices and automatic fire-prevention devices, security system of the complex, dispatching systems, structured cable network and local computer network of the complex, which belong to the group I power supply category.

Power supply to the building loads shall be carried out according to the following scheme:

In the premises to be rented - from the local switchboards tenants. Power supply of these panels from the outlet floor units from the bus duct.

In rooms, hotels - from local floor distribution boards. Power supply of these panels from the outlet floor units from the bus duct.

General floor loads (lighting, sockets, fan coils, etc.) in the building owner's premises - from lighting and socket distribution boards. The building owner's switchboards are powered directly from the main switchboard in a radial arrangement.

Central engineering equipment - from the automation boards in the rooms of engineering equipment. Automation boards are powered directly from the fire compartment switchgear. Automation boards used to connect fire loads are powered from different sections with the organization of the ATS at the input of the board.

Building refrigeration center (chillers, dry coolers, pumps, etc.) - directly from the main switchboard by a bus duct to the refrigeration center switchboard;

Equipment of the automatic fire extinguishing station - directly from the main switchboard to the automatic fire extinguishing switchboard.

Electric power supply to the building loads shall be carried out according to the following scheme:

GRSh-1 (see Appendix 1) provides power supply:

- CDC refrigeration center

Main switchboard-2 (see Annex 2) is envisaged for power supply to

- rental space of the office part;

- the supply and exhaust ventilation of the office parts;

- firefighting systems of the office part, through the switchgear of the fire compartment (switchgear-PO4);

- elevators of the office part.

GRSh-3 (see Appendix 3) provides for the power supply:

- refrigeration center CDC

- consumers of the restaurant, including the supply and exhaust ventilation;

- loads of apartment floors, including supply and exhaust ventilation and elevators;

- loads of heating and ventilation systems;

- loads of parking;

- loads of automatic water fire extinguishing installations.

From the switchgear-rest receives power supply the following equipment:

- technological equipment of the restaurant;

- supply and exhaust ventilation;

- restaurant lighting;

- restaurant loading elevators.

This switchgear-rest provides power to the fire load of the restaurant, i.e. this switchgear supplies power:

- automatic fire alarm system of the restaurant;

- smoke exhaust and overhead systems of the restaurant;

- In order to fulfill the power supply to the cooling centers located on the 8th floor and on the roof, two bus ducts are laid from the main switchboard panels with connection of the loads to the switchboards 8 and 15 (on the roof) located in the specialized rooms - storerooms.

For power supply of office areas, two bus ducts running from the main switchboard to the 14th floor are provided. Each bus duct has the possibility of installing tap-off units to connect the load on each floor.

The following structure has been adopted for the installation of units:

- for busbar 1 - floors 2, 4, 6, 9, 11, 13.

- For 2nd busbar - floors 3, 5, 7, 10, 12, 14.

In addition, each busbar can be equipped with a tap-off unit on a non-main floor.

Bus ducts and diverter units shall be installed in special risers. The outlet on each floor is provided in a special room in the electrical room.

In this room also pass the vertical cable structures for the main power supply, as well as the power supply of fire suppression systems.

The following equipment shall be installed in these switchboards:

- branch units;

- office load switchboard;

- switchboards with electricity meters;

- fire load switchboard of the floor;

- work light switchboard;

- switchboard duty lighting;

- control panel.

From the main switchboard is the installation of the main cables of normal and emergency power supply to the PSU. From the PPU provides power to all loads within the compartment.

There are two elevators in the complex (elevator № 7 and № 9) for the transportation of fire-fighting units. These elevators are powered by I power supply category.

Provide for the laying of cable lines from the floor switchboards on the premises of the office rented part with the installation of shields mechanization. The number of switchboards to provide the following, depending on the area of the premises:

The area of up to 100 m - 1 panel;

Area from 101 m to 500 m - 2 shields;

Area from 501 m to 1000 m - 4 shields;

Area from 1001 m up to 2000 m - 6 shields.

The area from 2001 m and more - 8 panels.

The power supply to the Tenants shall be carried out by the following means:

Lease space from 1 to 14 floors of the office part. Power supply of the premises is carried out from the main switchboard. Trunk busbar with the installation of tap units in each storey switchboard, with the installation of two circuit breakers. Hotels. From the main switchboard installed in the control room. Trunk bus ducts with the installation of tap-off units in two in each storey electric room, with the installation of circuit breakers. Lessee switchboards are not included in the scope of the design and are performed by a competitive Lessee after the conclusion of the lease agreement. In addition to the electrical switchboard rooms, electrical switchboards for powering technological systems are installed in the technical rooms in which these systems are located - the heating station, boiler room, ventilation rooms, etc. The bus ducts of the apartments and the outlet units run in special risers. The outlet on each floor is provided in a special room electrical switchboard. In this room also pass vertical cable structures for the main power supply, as well as the power supply of fire-fighting systems.

The following equipment shall be installed in these switchboards:

- withdrawal units;

- distribution board for the load of the apartments;

- switchboards with electric meters;

- fire-fighting floor load switchboard;

- work light switchboard;

- switchboard for duty lighting;

- control panel.

The cross-section of cables going to the floor distribution boards and for tenants is selected so that they have a 20% margin over the rated capacity. Automatic circuit breakers shall be installed in the floor distribution boards for power supply to the offices, DIN -rails for mounting. The power panels in the offices are carried out by the Tenant on a separate project at the stage of the working documentation. On the floors of the building group distributions for low-power equipment, to sockets, lighting fixtures, fancoils, dehumidifiers and other small electrical loads should be carried out, as a rule, by multicore cables VVGng- LSThe cables are laid in rigid PVC pipes and/or on steel trays. Cables are routed in pipes, on the surface of walls, in the grooves, in gypsum board walls. Shields are installed in pumping stations, ventilation chambers, rooms of external units of split systems and precision air conditioners, next to the serviced equipment. In case of outdoor installation of the equipment, the control panels are installed in the nearest technical room. The automation panels for technological equipment will consist of switching equipment, controllers, automation circuits, and auxiliary power and low-current equipment. The scope of this section of the project includes power supply to the automation boards, and cabling from the automation boards. The installation of the power supply cables from the automation boards to the specific equipment is performed in the automation section. The supply of the switchboards themselves (both power and secondary parts) is included in the automation section, which is issued in a separate section.Similar to the other electrical switchboards, the motor automatics switchboards will comply with IEC 439-1 and have metal housings. At a minimum, they will be of the following design IP 31, and in wet and/or dusty environments up to IP 54. Each panel of the electric motor automation of fire protection systems (smoke and smoke exhaust and chimney systems) is powered from the PPU of the fire compartments for which are provided. The power supply of these panels is organized through an automatic transfer switch (AVR) from different sections of the automatic fire system (powered from different transformer substations) by I reliability category. For power supply of the equipment is supposed to use cables like VVGng- LS of corresponding cross-sections along the cable structures or in PVC pipes. For power supply of firefighting equipment it is assumed to use cables of VVGGng- FRLS of corresponding cross-sections with the required fire-resistance rating, laid along separate routes and risers.

The distribution network from each main switchboard is carried out in vertical cable shafts and then through a horizontal system of conduits. For the arrangement of horizontal sections of networks, galvanized perforated boxes are provided for open wiring, as well as behind suspended ceilings. Cabling in the space behind the false ceilings and inside the prefabricated partitions are considered hidden, and are performed as follows:

- Behind suspended ceilings and voids of partitions made of non-combustible materials of NG and flammability group G1, wiring shall be made with wires or cables in nonmetallic pipes and nonmetallic ducts, and cables with the HG and LS indexes which meet the requirements of fire safety;

- Behind suspended ceilings and in cavities of partitions made with combustible materials G2, wiring shall be carried out with wires or cables in metal pipes and metal ducts with a minimum degree of protection IP4X;

- Behind suspended ceilings and in cavities of partitions made with combustible materials of flammability group G3, the wiring shall be made with cables in metal pipes and metal ducts with a minimum degree of protection IP4X;

- Behind suspended ceilings and in cavities of partitions made with materials of flammability group G4, the wiring shall be made with wires or cables in metal conduits with containment rating as well as in metal blind ducts with containment rating.

Cables laid in electrical recesses and shafts shall be of a fire hazard class not lower than that stipulated in paragraph 3 b of NPB 248-97. 3 b NPB 248-97. FRLS type fire-resistant cable shall be used for the circuits from the ATS panels to the fire control panels. Electrical circuits supplying fire-fighting systems and devices within the fire compartment to be served shall be laid in insulated ducts surrounded by fire partitions with a fire resistance rating of REI 60, outside the compartment - REI 150 with horizontal strips in the floor level or be made with cables with appropriate fire resistance rating. Passageways through ceilings or walls must be made through certified cable penetrations with a fire resistance rating not lower than the wall or ceilings. Cross-section of conductors shall be at least 1.5 mm for light fixtures, 2.5 mm for 10/16 A current collectors, 4 mm for 20 A current collectors and 6 mm for 32 A current collectors. To ensure reliable power supply at the input of each main switchboard ATS scheme is assembled, switching consumers to a working transformer in an emergency situation. In addition, AVR panels are installed to supply power to consumers of fire protection systems - smoke and air exhaust fans, sprinkler/draincher system pumps and others. These panels are connected to each section of the main switchboard. Each ATS panel provides voltage contacts on the inputs for the building dispatching system. At the entrance to the underground parking lot shall be installed three-phase AC outlets with power to I reliability category for the connection of fire and technical equipment. Technical premises are equipped with a network of 36 V outlets for maintenance lighting. In the corridors, lobbies, lobbies, underground parking provide network of outlets for cleaning equipment.

-

Electrical lighting.

According to the requirements of SP 52.133330.2011, the project will have the following lighting:

working;

emergency;

evacuation;

repair;

decorative lighting (lighting of facades);

exterior lighting (lighting of the adjacent territory of the complex);

architectural lighting of facades, including holiday lighting and advertising;

temporary lighting of the leased space for the period of finishing of this space.

All the premises of the complex have operative lighting, which complies with the requirements of SP 52.133330.2011 and SP 31-110-2003. The energy-efficient lamps with fluorescent lamps T5, T8, CLL and electronic control gear will be used in the premises. The service and technical rooms and technical areas (those that do not require a special design) will mainly be lit with energy-efficient luminescent lamps. For external lighting of exits (entrances), luminaires with energy-saving fluorescent lamps are used, if not with incandescent lamps. The values of illumination, safety factors and quality indicators of the lighting installation are taken into account when designing the electric lighting of the complex in accordance with SP 52.133330.2011 "Natural and Artificial Lighting".

The calculation of the required power for the lighting panels is made taking into account the following levels of illumination in the premises:

Office/trade premises (general) - 300-500 lux;

Corridors and staircases, stairwells - 150 - 200 lux;

Lobby and entrances - 250 lux;

Technical premises - 150 lux;

Parking lot - 75 lux.

Lighting in other rooms complies with standards SP 52.133330.2011 and MGSN 2.06-99. All working lights shall comply with the requirements of IEC 598-1 and IEC 598-2. Work lighting systems are designed to provide comfortable lighting with good color rendering. In areas where people are constantly present, all fluorescent lamps have a color rendering index (CRI) of at least 85. To avoid flicker, fluorescent luminaires should use high-frequency ballasts, except for temporary lighting fixtures in unfurnished rental spaces. The color temperature (CCT) of fluorescent lamps should be between 3,500 and 4,000 K. Lighting of rooms equipped with displays is performed by fluorescent fixtures with direct light, which have a limited brightness in the area from 50 to 90 ° from the vertical. Fixtures are arranged in rows so as to eliminate the reflected glare on the screens. Elevator shafts, as well as machine rooms, the area in front of the shaft doors, passageways and corridors leading to the elevator are equipped with fixed lighting. Stairwells without natural lighting shall be equipped with emergency lighting fixtures. Enclosures, IP degree of protection and external temperature tolerance for all luminaires have been selected for their suitability for the places where they will be installed. All the luminaires in the sanitary facilities, engineering and technological equipment rooms, landing stages, technical corridors, unloading and loading corridors and parking lots are equipped with protective shields.

The system of working light control will depend on the type of room and is carried out as follows:

In the individual rooms of the building owner (administrative and household premises, technical, engineering equipment, auxiliary, warehouses, landing stages) - by means of local switches;

In the public areas of the complex - by means of local switches, with division into zones;

In the premises for rent - individually for each leased premises.

There are measures to ensure the life activities of people with low mobility (persons with disabilities) in terms of installation of switches at a height of not more than 0.8 m from the floor, as well as in rooms (toilet cubicles, elevator halls, corridors, etc.), where a citizen of persons with disabilities may be located, emergency lighting is provided. The illumination of these rooms (accessible for the MSM) is designed one level higher in comparison to the requirements of SP 52.133330.2011. Emergency lighting fixtures shall comply with the requirements of GOST R MEK 60598-2-22-99. The emergency lighting panels are to be powered by power supply category I from different transformer substations. Evacuation and safety lighting is carried out by lighting fixtures complete with emergency battery kits (battery, charger, inverter, voltage control relay). These lights will be part of the emergency lighting system, but will be powered in separate groups from dedicated emergency lighting panels, without switches. Battery packs will be designed to work for at least 1 hour at its full load (for the time of evacuation of people from the building). The project provides for the installation of a light board above the entrance to the pumping station APT - "Pumping fire extinguishing". On the facade of the building is designed to install light indicators of the location of fire hydrants, as well as light pointers street name and number of the house. The automatic activation of light indicators for fire hydrants and the direction of movement when fire automation systems are triggered is envisaged.

The emergency lighting is provided in all rooms and areas of the building in accordance with the requirements of SP 31-110-2003 and SP 52.133330.2011. Evacuation lighting is provided in corridors, halls, foyers and lobbies, on the stairs used to evacuate people, in the sales rooms and on the ways out of them, in the production facilities of catering enterprises. The evacuation lighting will be provided in all public spaces with more than 20 people in the air conditioning chambers, pump rooms, electric rooms and in all other spaces without natural light according to PB 52.133330.2011. The illumination achieved by the system of evacuation lighting will not be less than 0.5 lux at floor level.

The evacuation lighting will be powered and controlled from the central emergency lighting system. The evacuation (standby) lighting will be controlled only remotely and only from special enclosed spaces. In addition to the control panel of the central emergency lighting system, there will be remote control from 2 locations: from the fire station and the guard post. The network of working, emergency, evacuation and exterior lighting is powered by ~ 220 V, 50 Hz. As a

-

Grounding and lightning protection.

The GDC is equipped with one common grounding device. The common grounding device performs the function of protective and functional grounding as well as lightning protection grounding. The power supply of the MCC is carried out from 10/0,4 kV power transformers with deaf-earthed neutral. For attached transformer substations an external grounding loop is made in accordance with the requirements of the TP project. The resistance of the grounding device for the transformer substation shall be at least 0.5 Ohm. The impedance of the earthing device of electrical installations up to 1 kV must not exceed 4 ohms at any time of the year. According to the paragraph 1.7.101 PUE the resistance of the earthing device for electric installations of a building with voltage up to 1 kV to which the neutral point of the transformer is connected at any time of the year must be less than 4 Ohm at line voltage of 380 V of three-phase current source or 220 V of single-phase current source. Neutral grounding system of transformers is accepted type - TN-C-S - system, in which the transformer neutral point is permanently grounded, and the exposed conductive parts of the electrical installation are connected to the permanently grounded neutral point of the source through zero protection conductors, where the functions of zero protection and zero working conductors are combined in one conductor in its some part, starting from the power supply. According to clause 1.7.55 of the PUE: "For grounding in electrical installations of different purposes and voltages, territorially close, as a rule, one common grounding device should be used". Based on this requirement, the external grounding circuit for the attached TP and the electrical equipment of the building will be common.

The division of the combined PEN conductor into a protective earth conductor PE and a working earth conductor N takes place in the main switchboards.

The following electrical safety measures are employed to protect against electric shock in the event of damage to the insulation:

earthing/grounding using a PE protective conductor;

equipotential bonding system by earthing all metal conduits, air ducts, enclosures of panels, electrical wiring pipes, cable structures and other similar equipment that can be energized if the insulation of the wiring is damaged;

protective shutoff (RCD) - shall be installed in switchboards of power outlets, whose sudden shutoff would not result, for technological reasons, in situations that are dangerous to the user and maintenance personnel; in outdoor lighting switchboards;

low voltage, less than 42 V - outlets up to 36 V for repair purposes in technical premises.

Grounding of the electrical equipment is carried out by connecting the supplying line conductor to the PE bus of the main switchboard PEN.

The following grounding systems are organized in MCC:

protective earthing - connection of exposed conductive parts to the earthing device using PE conductors included in cables or laid separately.

Operational (functional) grounding - connection of LAN equipment and other low-current systems of the building to the main grounding bus (MGE) or to a separate grounding unit with separately installed PE conductors. The neutral operating conductor and the neutral protection conductor must be part of the same cable. Separately laid PE conductors must be mechanically secured. As a protective measure in the event of an indirect contact, an automatic power disconnection and equipotential bonding shall be applied. To ensure fire safety, residual current devices up to 300 mA are installed on the inputs of the distribution boards of the apartments. To reduce the risk of electric shock when using electrical appliances, protective disconnection devices with a leakage current of 30 mA have been installed in group outlet lines. The main system of equipotential bonding is fulfilled in the complex.

The main equipotential bonding system connects the following conductive parts:

zero protective PE- or PEN- conductor of the supply line;

Metal pipes of the utilities that are part of the building: hot and cold water supply, sewerage, heating, etc;

metal parts of the building framework;

metal parts of centralized ventilation and air conditioning systems. In the presence of decentralized ventilation and air conditioning systems, metal ducts must be connected to the busbar PE power supply boards of ventilators and air conditioners;

an earthing switch for the lightning protection system;

The grounding conductor of the functional (working) grounding, if it is available and there are no restrictions to connect the network of working grounding to the grounding device of the protective grounding;

Metal sheaths of telecommunication cables.

To protect against high potential drift through external (aboveground) metal communications it is necessary to connect them to a GZSH at the entrance to the MCC. For the building a set of lightning protection equipment is designed, which includes devices for protection against direct lightning strikes (outside

-

-

-