Working documentation of a structured cabling system SKS in the Building 2 of the Multifunctional Centre

Our company developed working documentation for the construction of a structured cabling system (SKS1) in the Building 2 of the Multifunctional Centre, address: Moscow.

Common data SCS

The working documentation for the construction of a structured cabling system (SKS1) in the Building 2 of the Multifunctional Centre, address: Moscow, is executed in accordance with:

-

Terms of reference for the development of working documentation;

-

Agreed stage "P";

-

Architectural - construction plans;

-

Technical solutions agreed with the customer.

The working documentation is made in accordance with the following regulations:

-

GOST 21.1101-09 ASAP. Basic requirements for the design and working documents;

-

GOST R 53246-2008 "Information Technology. Structured cabling systems. Designing the main system components. General requirements ";

-

GOST R 53245-2008 "Information Technology. Structured cabling systems. Installation of major system components. Test methods ";

-

GOST 21.406-88 "Wired communication. Graphic designations in the schemes and plans ";

-

GOST R 21.1703-2000 "Rules of execution of working documentation wired communications";

-

TIA/EIA-568S «Commercial Building Telecommunications Wiring Standard (American Standard)";

-

ISO / IEC IS 11801-2002 Information Technology. Generic cabling for customer premises (International) ";

-

ANSI/TIA/EIA-568-B3-2000 «Optical fiber cabling components standard», 2000 (Fiber components of structured cabling systems), 2000;

-

ANSI/EIA/TIA-569 «Commercial building standard for telecommunications pathways and spaces», 1990 (Conduits and technological facilities for telecommunications in buildings commercial organizations), 1990;

-

ANSI/TIA/EIA-606-A-2002 "Standard Administration telecommunications infrastructure of commercial buildings";

-

SNIP 3.05.06-85 "Electrical devices";

-

PUE ed. 6, 7, "Electrical Code";

-

Engineering and technical recommendations and minimum standards for ERMS v.4.0.

SCS to build components for structured cabling SYSTIMAX manufactured by CommScope. For use in the assembly materials produced by Russian manufacturers.

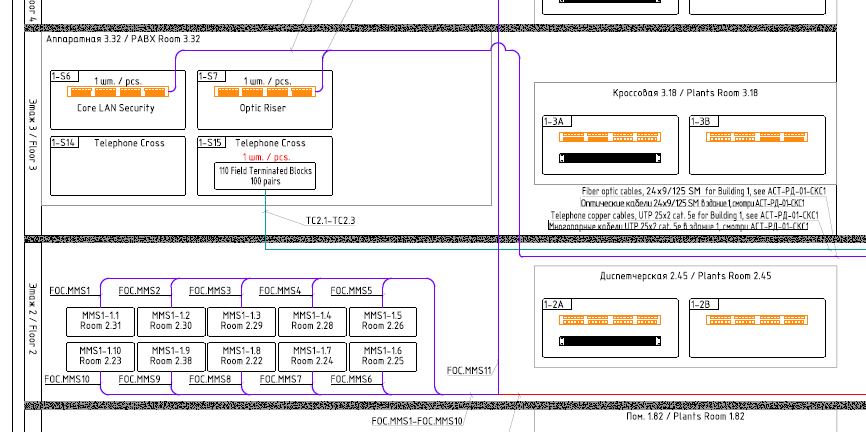

Crosses SCS and subscriber outlet installed in accordance with the plans of arrangement of equipment.

All SCS components must be labeled in accordance with this document and the recommendations of the working standard ANSI/TIA/EIA-606-A-2002.

The principle of labeling should provide an unambiguous identification of the component of SCS on purpose, specifications and location.

The marking shall be resistant to wear and easy to read.

Marking elements cabling applied in an accessible place for observation. The basic principle - to assign each feature a unique alphanumeric number that describes the functionality and installation location.

Upon completion of installation work to make testing the cable system. Installed equipment is not a source of emissions.

Special measures to protect the environment is not required.

After installation, perform testing of installed copper and fiber optic lines to conform to the SCS category and passing standard protocols tester cable lines with the generation of standard measurement protocols.

Results of testing protocols and arrange transfer to the Customer.

All metal enclosure systems SCS must be securely grounded. Ground cable from the respective boards in the building connected to the earth closet.

Grounding perform in accordance with the requirements ANSI/TIA/EIA-569-A, GOST 464-74, GOST R 50571.10-96, RB.

The system is a complete specification of equipment, products and materials.

Installation work must be performed in accordance with this working documents and reference documents listed in accordance with the technical description of the equipment, strictly observing the requirements of safety and fire safety.

SCS cables pave Tripless not allowed twisting, adhesions, physical disturbance isolation, cable breaks. The maximum cable length from the information outlet to the patch panel should not exceed 90 m Cutting of cables made after soundings routing of the place. When laying the manufacturer to comply with recommended cable bend radius, the maximum tensile stress, and techniques routing and mounting cables. Cable tray must be carefully laid out and sozhgutovany. Upon completion of installation, there must be a residual tension of the cable. When attaching the plastic cable ties to the trays is recommended to use a special tool to avoid kinked cable tie.

Number of fixing the cables to the tray at least three risers on the floor.

Maximum step of fixing the cables to the trays 300mm.

Cable SKS1 be crossed cable runs electrical distribution networks at an angle of 90 °.

All drilled holes must be sealed fire-resistant materials in accordance with the degree of fire resistance of walls, slabs

Ret cables for input tray into the room to perform in PVC pipe.

Perhaps the change of routing cables because bypass engineering equipment. Changing the number of cable when it is necessary to agree with the customer and project organization.

For joint cabling in line cables of different types in the first place to install fiber-optic cables are the backbone subsystem, then horizontal cable.

Fiber-optic cables terminate in optical shelves using splice plates and finished pigment Tale by welding.

Organization of external networks in this project is not provided.

The organization provides intra STAY working documentation

Installation and repair work in electrical networks and devices (or near), as well as work on the connection and disconnection of wires should be performed only when de-energized. Cabling and installation carried out in accordance with the requirements of SAE, SNIP 3.05.06-85, SNIP 12-03-2001; SNIP 12-04-2002.

Accommodation designed equipment made in view of the existing rules on the protection of health and safety.

Work must be performed by a professional installation organization.

Russian version of the main.