Access control design access control for office floor

Our engineering organization has developed working drawings and completed the installation of access control systems (access control systems) in the tenant's repaired office. Faced problems in the interaction with subcontractors who made the finish and did not want to know anything about the observance of the sequence of work. Nevertheless, the system is implemented perfectly, the customer is satisfied.

DESIGNING OF ACCESS ACCESS CONTROL SYSTEM

THE MAIN TECHNICAL SOLUTIONS OF ACS

3.1. BOLID equipment is used to organize access control systems.

3.2. The system is based on a PC (Server) with the Orion Pro software installed. For management

ACS is used S2000M. The server and the central control panel are installed in the room №18 "Server" on

1st floor.

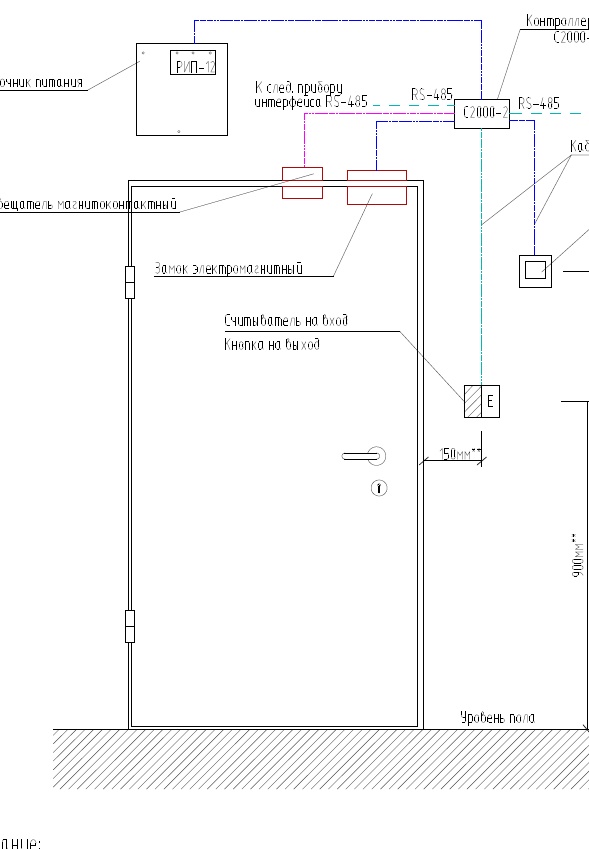

3.3. Communication between devices is carried out via RS-485 interface. The device is used to control passage zones

S2000-2. To open the doors in automatic mode in case of fire, the SPA project provides a transponder 808623

(23.3.1TP6), which controls the power supply circuit of the switching device of the type UK-VK, which, in turn,

controls the power supply circuit of the electromagnetic lock. Also installed a manual detector, which when pressed

opens the power circuit of the lock. When receiving a "fire" signal from the automatic fire control system, relay blocks

open the power supply circuit of the locks, thereby ensuring an unobstructed exit from the premises. Train from

spa transponder looped back.

3.4. ACS provides the following features:

• automatic access control at points of entry based on the analysis of information on

according to the identification code of Proximity contactless cards issued by individuals,

the date and time of passage allowed for a given level of access;

• entrance to the premises by several identifiers (only a few people can open the door,

meeting and presenting your cards);

• prohibition of double pass (anti-passback function);

• issuance of the state of any object of the system (point of passage) at the request of the operator;

• Operator’s operational control of the entire system as a whole, as well as individual objects (doors);

• maintaining a database of cards containing detailed information (including a photo) about the owners

plastic cards;

• an intuitive graphical interface that allows you to display events on the monitor in text and

graphics modes, i.e. work with the program to security staff who do not have

special training;

• the password system restricts the operator in his actions in accordance with his authority;

• all operator actions are logged in the system log;

• processing, saving all system messages, issuing reports in a convenient form for any given

criteria (date, time, last name, department, reader, security loops, message type, etc.).

3.5. The executive devices of the personnel access control system are electromagnetic locks.

3.6. Access controls and controls include:

• 7 door controllers "S2000-2";

• 6 electromagnetic locks "AL-250SH";

• 8 readers "Proxy-3MA";

• 10 buttons of contactless type "Magic-M";

• 6 buttons to unlock;

• 1 turnstile "Rostov-Don T2MM1"

PROJECT DOCUMENTATION ACS

3.7. Each point of access control is equipped with the following equipment:

• proximity card reader - "Proxy-3MA", for the turnstile 2 pcs;

• access controller connected to the system via a common data bus - "BOLID C2000-2";

• control button of the contactless type "Magic-M", for the turnstile 4 pcs;

• magnetic sensor, for monitoring the status of the door - "IO 102-6P" or built-in

turnstile passage sensor;

• electromagnetic lock - "ExCon AL-250SH" or a lock built into the turnstile;

• automatic door closer - "comes complete with a door" or built into

turnstile closer;

• door emergency unlock button - "BOLID EDU 513-3M ISP.01", the turnstile does not;

• uninterruptible power supply - "BOLID RIP-12-1A-7A / h Protection 2".

3.8. The layout of the equipment and cable routes of the access control system can be found on page 5 of this project.

3.10. Cable lines for connecting ACS equipment are performed:

• KVPng (A) -HF-5e 2x2x0.52 - RS-485 interface cable and button connection;

• KVPng (A) -HF-5e 1x2x0.52 - connection of magnetic contact detectors;

• PPGng (A) - HF 2x1.5 - power supply circuit of electric locks;

• FTP, 4 pairs, cat 5e, LSZH - connection of readers;

• PPGng (A) - HF 3x1.5 - power supply line of redundant power supplies.

3.11. Laying of the ACS cable in the raised floor and false ceiling spaces, as well as in the plasterboard walls

Perform in corrugated pipes made of non-flammable PVC. Fasten the pipes by

typical drawings of the manufacturer (DKS)

3.12. Joint laying of ACS cable lines with lines of 110 V and more in

one box, pipe, harness, closed channel of a building construction or on one tray. Joint

laying of the indicated lines is allowed in different compartments of boxes and trays having continuous longitudinal

partitions with a fire resistance of 0.25 h of non-combustible material.

3.13. Cutting cables to make after control promera laying routes with regard to the location

projected equipment.

3.14. Clearances at pipe penetrations through building structures should be sealed

fireproof materials.

3.15. When laying cable lines, observe the minimum distances to building constructions,

power trays and cables, consider the location of engineering equipment of adjacent sections -

a slight adjustment of the route of cable lines based on

The above and other local installation conditions.

3.16. Bind cable lines vertically and horizontally in place.

3.17. Working drawings are designed in accordance with applicable regulations, rules and standards.

3.18. All work must be carried out in accordance with the safety regulations for

performance of these types of work. Workers are allowed to work only after passing

safety instructions.

4. ELECTRICAL SUPPLY AND GROUNDING ACCESS

4.1. Access control system refers to the third category electric receivers according to the degree

ensure the reliability of power supply in accordance with the EMP. Power equipment must

be carried out from separate groups of electrical panels powered from the main switchboard of the building according to category III.

4.2. Power supply ACS to carry out from the AC network 1F, 220V, 50Hz.

4.3. The devices are powered from the backup power supply sources RIP-12-1A-7A / h Protection 2.

Power sources are supplied from the AC network 1F, 220V, 50Hz.

4.4. The power consumption of the system is calculated on the basis of currents, according to the characteristics of the manufacturer

modules used.

Power calculation table:

5. INSTRUCTIONS FOR INSTALLATION ACCESS

5.1. Electrical work should be carried out in accordance with SP 6.13130-2013, the governing document

RD 78.145-93 "Systems and complexes of the security, fire and security and fire alarm system. Rules

production and acceptance of work. "

5.2. Controller, power unit to install in the space behind the false ceiling above the controlled door

from inside the controlled room. Readers and "exit" buttons set at a height of 0.9 m. Buttons

Unlock set at a height of 1.5 m from the floor level.

5.3. With parallel open laying the distance between the wires and cables of the alarm loops and

connecting lines with power and lighting wires must be at least 0.5 m. Allowed

reduction of the distance to 0.25 m from the wires and cables of the fire alarm and connecting cables

lines without interference protection to single lighting wires and control cables.

5.4. Before installation work:

- check the integrity and operability of the equipment.

- prepare materials, component parts and tools.

5.5. The condition of cables and wires before installation is checked by an external examination. In addition to inspection

the cable is routed and the integrity of the core insulation is checked.

5.6. To eliminate interference from the electrical network, laying low-voltage lines is performed at a distance

not less than 0.5 m from power circuits and lamps.

5.7. The distance from the cables and insulated wires of the access control system, laid open,

directly on the elements of building structures of the premises to open storage

(placement) of combustible materials not less than 0.6 m.

5.8. The frequency of maintenance of devices and modules in accordance with the technical description and instruction

for use on each product.

5.9. Installation of equipment must be done in compliance with safety regulations, rules

technical operation, operational documents for installed products.

5.10. To protect people from electric shock during assembly work all

non-conductive, but capable of being energized due to insulation failure, metal parts

electrical equipment must be grounded, according to the requirements of the EMP.

5.11. All conductors used as grounding are securely connected to the PE bus in

switchboards. For this purpose, 3 and 5-wire power cables with special

grounding conductor with yellow-green marking.

5.12. The working draft was made in accordance with the Safety Rules and requirements of the system.

occupational safety standards (SSBT), which include sanitary and technical measures that

ensure compliance with the following standards:

- GOST 12.1.003-83 SSBT "Noise"

- GOST 12.1.004-91 SSBT "Fire Safety"

5.13. In the premises during the installation works to ensure the temperature and humidity, according to

norms.

5.14. The list of types of work for which it is necessary to draw up certificates of examination of hidden works:

- laying of cable lines of the access control system in the area of false ceilings;

5.15. Upon completion of installation and commissioning works by the installer must be completed

executive documentation taking into account changes made to the working documentation during production

assembly work.