Design of the refrigeration center automation for several office buildings

Completed the project AHS. Completed the project installation, programming and commissioning of the automation system of the refrigeration center. This refrigeration center supplies 3 office buildings with coolant, consumes 1.6 MW of electrical power. The largest HTC of those that we mounted at the moment.

DESIGNING THE AUTOMATION OF THE COOLING AHS

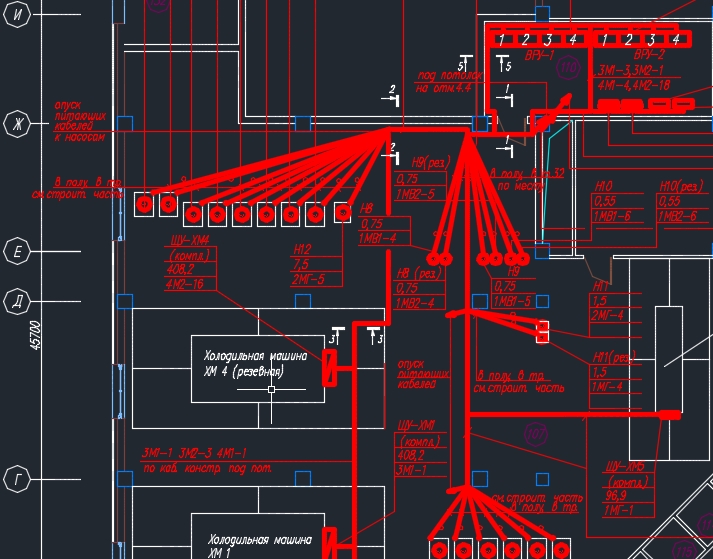

This project was carried out on the basis of the tasks of related specialties in accordance with regulatory documents. The project provides for power supply of power electrical equipment of the refrigerating center of the power unit. The main electric receivers of the refrigerating center are: - refrigerating machines (ХМ1-ХМ5); - cooling towers (N1.1-1.4, 2.1-2.4, 3.1-3.3, 4-1-4.4,5.1); - electric motors of network pumps (H1, H2, H3, H4, H5, H6, H7, H11, H12); - electric motors for make-up pumps (H8, H9, H10). The power consumption of power electrical equipment of the refrigerating center is Rp = 1662.8 kW, of which 1067.8 are refrigerating machines.

In terms of power supply reliability, power consumers of the refrigeration center belong to category II according to PUE, except for the refrigerating machine HM-5, pumps H1, H2, H11, H12, cooling towers 5.1, which are powered from DES (via ATS) in case of emergency loss of electricity. VRU-1, VRU-2, VRU-3, VRU-4 input distributing devices and ShchGP-1, ShchGP-2 uninterruptible power supply boards are used for power distribution, which are installed in floor-standing panel switchboards 110,213. Introduction distributing devices VRU-1 and VRU-2 are designed to power the pumps of refrigerating machines, and VRU-3, VRU-4 - to power the cooling towers. Boards ShchGP-1, ShchGP-2 are designed to power the power consumers requiring a guaranteed power supply (chiller XM5, cooling tower 5.1; pumps H1, H12 serving the HM5 and pumps H1, H2, which normally work from the network, and in the emergency mode from a diesel power plant ). Chillers HM-1-HM4 are powered directly from the KTP-3,4 switchboards. Control panels for refrigerating machines (SCHU-HM) are supplied complete with refrigerating machines. The power cables to XM1-XM4 will be included in the arch.L817-326. Control of the cooling tower fans is performed from the control panel of the control panel, supplied complete with cooling towers. Cables from SchU control panel to regular cooling tower fans. As starting equipment for network pumps, the device is used for the soft start-up “Altistart” of the firm “Schneider-Electric” and, additionally, bypass power supply with the help of the pump control unit BUN. For blocking the activation of the pump control system, see the automation project. Control of pumps is local (from the control panel) and automatic (see the project of automation). Group networks are performed by cable VVGng-LS: - open in trays on cable structures; - hidden in steel pipes in the floor (see the construction part of the project) and in the risers. In places where cables pass through walls and interfloor overlaps, in order to prevent water from penetrating and accumulating and spreading fire, gaps between the cable and the pipe with paging material made of combustible material should be sealed. The supply of power cables to the electric motors of the pumps should be made with a flexible cable of the KG brand in the metal hose from the U994 junction box installed on the electrical wiring pipe.

PROJECT DOCUMENTATION OF COOLANT OF THE HLADOCENTER

Pipes are accounted for in the construction part of the project. The project adopted power supply networks with the type of current-carrying conductor system: - single-phase three-wire; - three-phase five-wire. with the type of grounding system TN-S. Protective measures are envisaged in accordance with the requirements of chapters 1-7 of the EMP, GOST R 50571 and other regulatory documents. Installation and protective measures to perform in accordance with the current EIR and SNiP. LIST OF WORK TYPES FOR WHICH IT IS NECESSARY TO DRAW UP THE CERTIFICATES OF HIDDEN WORKS Hidden wiring in pipes in the floor.