Automation design of a gas boiler room for a warehouse complex

Completed a construction and installation project, programming and commissioning of a boiler room automation system for our project.

DESIGNING OF BOILER AUTOMATION

1. Baseline data of the boiler house automation project and the main provisions

The project of automation of engineering systems is carried out on the basis of the following documents:

- contract for the design of automation systems and scheduling engineering systems;

- technical specifications of adjacent sections;

- technological and construction drawings;

- current regulatory documents:

|

СНиП 31-04-2001 |

"Warehouse buildings" |

|

SNiP 2.08.02-89 * |

"Public buildings and facilities" (Ed. 2002) |

|

SNiP 2.09.04-87 * |

"Administrative and residential buildings" |

|

SNiP 21-01-97 |

"Fire safety of buildings and structures" |

|

SNiP 2.08.01-89 * |

"Residential buildings" |

|

SNiP II -01-95 |

"Instruction on the composition, procedure for the development of coordination and approval of design and estimate documentation for the construction of enterprises, buildings and structures" |

|

BCH 60-89 |

“Communication, signaling and dispatching engineering equipment for residential and public buildings. Design Standards |

|

PUE, ed.6, 2002 |

"Rules for electrical installations |

Considering the main purpose of the building, the project provides for the possibility of further expanding the network for dispatching and automation of engineering equipment. Additional control and monitoring panels with the necessary equipment may be located in the technical premises of the complex as the need arises to automate new systems.

This project includes:

- automation of boiler room systems - 2nd stage;

PROJECT DOCUMENTATION OF BOILER AUTOMATION

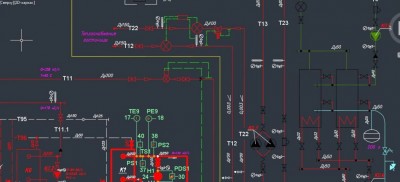

Structurally, the automation system is a network of control, freely programmable controllers installed in the boards (together with the power unit) at the place of installation of this or that equipment. The connection between controllers and external devices (drives, sensors) is carried out with the help of shielded cables, such as MKESH 2x1.0, 3x1.0, 4x1.0, the shields of which are properly grounded to avoid induced currents. The cabling of the automation system is carried out in separate metal trays, at a distance of at least 200 mm. from power wiring, and from trays to units in a metal corrugated pipe with a diameter of 16, 20, mm.

In addition to remote and automatic control of units, provides for "local" control, directly from the control panel; In addition, the project provides for installation of safety switches at the place of installation of units that are remote from the panel (pumps, general ventilation fans).

2. Basic automation solutions using Honeywell equipment .

2.1 To solve the problems of automating the Boiler-house system, the project uses a complex of tools from Honeywell .

The complex includes:

- primary converters with unified output signal 0 ... 10V

(air temperature sensor, water (liquid) temperature sensors;

- differential pressure sensors with discrete output signal;

- drives of water valves and air dampers;

- freely programmable, multifunctional microprocessor controllers EXCEL 500;

- the device of communication of the personal computer with controllers - BNA ;

2.2. Installation of electric panels with controllers built into them is provided in the boiler room.

2.3 Systems management provides 3 modes:

- Local control of pump motors from control panels.

- Remote control (from the CDP premises)

- Automatic systems management.

2.4 Automatic control is carried out according to a predetermined program embedded in the controller.

2.5 In order to put the unit or the entire system into local control mode, the corresponding switch must be turned on or all switches on the control panel should be set to “On”

Local control mode should be used only when debugging systems and in case of emergency.

2.6 Automatic control panel with EXCEL 500 controllers provides:

- start to work in a certain combination and sequence of all system units;

- implementation of the necessary laws of regulation and management,

blocking dependencies;

- the inclusion of a backup pump motor when a worker fails;

- measurement of current parameters and transfer of their values to the CPD;

- control of the state of the equipment (enabled / disabled, accident);

- remote on / off systems from the CPD;

- transmission to the CPD of emergency and statistical information on

current technological processes.

3. Solutions for the automation of pumping systems.

3.1. To solve the problems of automation of the boiler room, a complex of means is provided with the use of combined electric control panels and automation. The complex includes:

- electrical control panels and automation with built-in controllers, located at the place of installation of the equipment they serve. The power characteristics of the ShchUK2 shield are as follows:

~ 380 V, 50 Hz, on the 1st category of power supply reliability,

- bus information exchange between controllers ( C - BUS ), physically representing a two-wire communication line.

3.2 Automation of the boiler room provides for:

- Management of the boiler room systems (on / off) from the dispatcher's workplace or automatically according to a temporary program.

- Control of the circulating pump in the automatic mode - changing the mode of operation of the system by the operator from the central computer depending on the season, or in the automatic mode according to the readings of the outdoor temperature sensor.

In the control panel ShchUK2 provides for the connection of an external signal from the PPP. Shutting off consumers, in order to increase reliability, is carried out at the "relay level", i.e., even when consumers work in manual or remote mode, it should

there is a guaranteed shutdown.

3.3 Dispatching boiler room systems provides for:

- obtaining information on the temperature and pressure of the supply and return coolant;

- obtaining information (graphically on the monitor of the CPD) about the presence of pressure drop at the pumps;

- obtaining information on the receipt of a fire signal to a particular control panel from the fire alarm station (hereinafter PPP);

- obtaining other statistical, preventive and emergency information.

3.4. Automation of the boiler room provides for the following functions:

- regulation of the temperature of the coolant (water) for the systems of agents supplied to the heating network according to schedule 100-68ºС;

- opening the valve when the temperature of the return water from the refrigerating center of the supply water temperature of the OV systems is exceeded and closing it in the reverse situation;

- automatic switching of pumps from working to standby in case of worker’s failure, changing “working” and “reserve” every 12 hours;

- to ensure the possibility of the following modes of operation of the pumps OV and cold supply:

- one for heat supply, the other for cold supply;

- two refrigeration pumps;

- shutdown of pumps at emergency low water pressure in front of them;

- safety functions in accordance with SNiP II-35-76 with amended N 1:

automatic stopping of fuel supply to burners with:

a) exceeding the nominal gas pressure higher than 50 mbar or lowering the gas pressure below the minimum gas pressure for the burner used;

b) extinguishing the torch torch;

c) the temperature of the water leaving the boiler rises above 110 ° C;

d) increasing the water pressure at the outlet of the boiler above 6 bar;

e) in case of gas pollution of the premises more than 10% of the lower flammability limit of natural gas;

e) when fire alarm is triggered

(when these protections are triggered, the boiler room should be started only by personnel);

in the event of a power outage and the restoration of its supply, ensuring the automatic start of the boiler room;

- cascade control of the number and capacity of the included boilers in order to stabilize the temperature of the water in the boiler circuit.