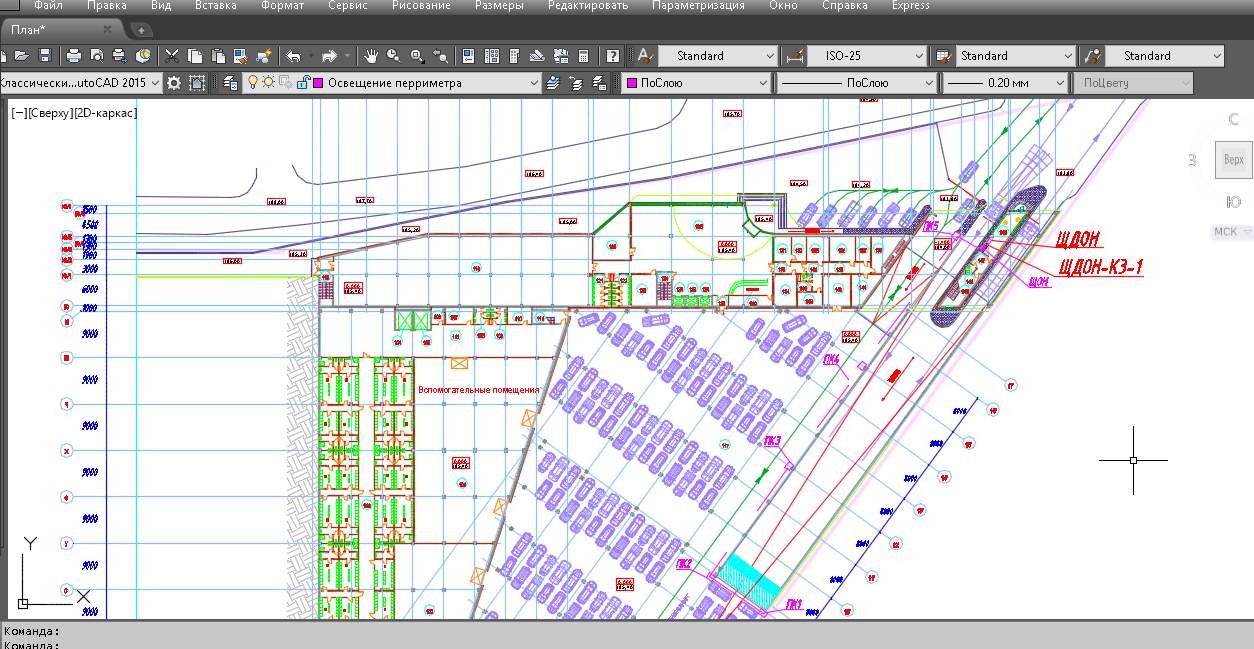

Automation and dispatching project for automated lighting control system for warehouses

Completed the installation and design of the lighting automation system for the automated process control system in the warehouse.

DESIGNING AUTOMATION OF LIGHTING

1. Baseline and Fundamentals

The project of automation of engineering systems is carried out on the basis of the following documents:

- contract for the design of automation systems and scheduling engineering systems;

- technical specifications of adjacent sections;

- technological and construction drawings;

- current regulatory documents:

СНиП 31-04-2001

"Warehouse buildings"

SNiP 2.08.02-89 *

"Public buildings and facilities" (Ed. 2002)

SNiP 2.09.04-87 *

"Administrative and residential buildings"

SNiP 21-01-97

"Fire safety of buildings and structures

SNiP 2.08.01-89 *

"Residential buildings

SNiP II-01-95

"Instruction on the composition, procedure for the development of coordination and approval of design and estimate documentation for the construction of enterprises, buildings and structures

BCH 60-89

“Communication, signaling and dispatching engineering equipment for residential and public buildings. Design Standards

PUE, ed.6, 2002

"Rules for electrical installations"

This project includes:

- automation of lighting and heating funnels;

2. The main decisions of the PROJECT asu.

2.1. For solving the problems of automation and dispatching of lighting and heating of funnels, a complex of means is provided with the use of an electrical control panel of automation and electrical control panels for lighting. The complex includes:

- electrical panels of automation with built-in controllers. The power characteristics of the automation panels are as follows:

~ 220 V, 50 Hz, according to the 1st category of power supply reliability, with one cable, from the device with the ATS function;

- electric control panels for lighting and heating of funnels, arranged according to the project. The design of these panels provides the ability to remotely control the lighting and heating of the funnels using potential-free (dry) contacts. The power supply characteristics of the lightning and heating hoppers are as follows:

~ 380 V, 50 Hz, according to the 2nd category of power supply reliability;

- wired lines of communication between the control panels for lighting and heating of funnels, and the switchboard of automatic equipment are laid with the MKSh cable.

- bus information exchange between controllers (C-BUS), physically representing a two-wire communication line.

2.2 The scheduling of switchboards, lighting panels and funnel heating includes:

- obtaining status information (on or off) graphically on the CDP monitor;

2.3 Automation of switchboards, lighting panels and funnel heating includes:

- Management of lighting and heating funnels shields includes:

remotely from the computer of the CPD or automatically according to a temporary program.