Design automation system for warehouse complex

Our organization has completed the design, installation, programming, and commissioning of the automation system for the VTZ heat curtains for a warehouse complex.

More under the cut ...

DESIGNING BACS AUTOMATION

1. Baseline and main provisions of the project

The project of automation of engineering systems is carried out on the basis of the following documents:

- contract for the design of automation systems and scheduling engineering systems;

- technical specifications of adjacent sections;

- technological and construction drawings;

- current regulatory documents:

СНиП 31-04-2001

"Warehouse buildings

SNiP 2.08.02-89 *

"Public buildings and facilities" (Ed. 2002)

SNiP 2.09.04-87 *

"Administrative and residential buildings"

SNiP 21-01-97

"Fire safety of buildings and structures"

SNiP 2.08.01-89 *

"Residential buildings"

SNiP II-01-95

"Instruction on the composition, procedure for the development of coordination and approval of design and estimate documentation for the construction of enterprises, buildings and structures"

BCH 60-89

“Communication, signaling and dispatching engineering equipment for residential and public buildings. Design Standards

PUE, ed.6, 2002

"Rules for electrical installations"

Considering the main purpose of the building, the project provides for the possibility of further expanding the network for dispatching and automation of engineering equipment. Additional control and monitoring panels with the necessary equipment may be located in the technical premises of the complex as the need arises to automate new systems.

This project includes:

- automation of the systems of heat curtains and heating units;

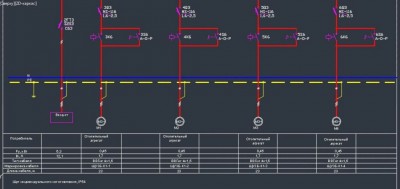

Structurally, the automation system is a network of control, freely programmable controllers installed in the boards (together with the power unit) at the place of installation of this or that equipment.

The connection between controllers and external devices (drives, sensors) is carried out with the help of shielded cables, such as MKESH 2x1.0, 3x1.0, 4x1.0, the shields of which are properly grounded in order to avoid induced currents. The cabling of the automation system is carried out in separate metal trays, at a distance of at least 200 mm. from power wiring, and from trays to units in a metal corrugated pipe with a diameter of 16, 20, mm.

In addition to remote and automatic control of units, provides for "local" control, directly from the control panel; In addition, the project provides for installation of safety switches at the place of installation of units that are remote from the panel (pumps, general ventilation fans).

2. Basic automation solutions using Honeywell equipment.

2.1 To solve the problems of automating the system of air curtains and heating units, the project uses a set of tools from Honeywell.

The complex includes:

- freely programmable, multifunctional microprocessor controllers EXCEL 500;

- the device of communication of the personal computer with controllers - BNA;

2.2 Indoor Thermal curtains and heating units provide for the installation of electrical panels with built-in controllers.

2.3 Systems management provides 3 modes:

- Local control of motor curtain and off. units from control panels.

- Remote control (from the CDP premises)

- Automatic systems management.

2.4 Automatic control is carried out according to a predetermined program embedded in the controller.

2.5 In order to put the unit or the entire system into local control mode, the corresponding switch must be turned on or all switches on the control panel should be set to “On”

Local control mode should be used only when debugging systems and in case of emergency.

2.6 Automatic control panel with EXCEL500 controllers provides:

- start in work in a certain combination and sequence of all units of the system;

- implementation of the necessary laws of regulation and management,

blocking dependencies;

- control of the state of the equipment (enabled / disabled, accident);

- remote on / off systems from the CPD;

- the transfer to the CPD of emergency and statistical information of current technological

3. Solutions for automating systems of heat curtains and heating units..

3.1. To solve the problems of automating the systems of heat curtains and heating units, a complex of means is foreseen with the use of combined electric switchboards of control and automation. The complex includes:

- electrical control panels and automation with built-in controllers, located at the place of installation of the equipment they serve. Power Specifications for Shields

SCHUZA-1, SCHUZA-2 and SCHUZB are as follows:

~ 380 V, 50 Hz, according to the 2nd category of power supply reliability,

- bus information exchange between controllers (C-BUS), physically representing a two-wire communication line.

3.2 Automation of Thermal air curtains and heating units includes:

- Control of the systems of heat curtains and heating units (on / off) from the workplace of the dispatcher or automatically by signals from the opening of warehouse doors.

The control panels of the Thermal curtains and heating units provide for the connection of an external signal from the PPP. Shutting off consumers of a shield, in order to increase reliability, is carried out at a “relay level”, i.e., even when consumers operate in manual or remote mode, they must be guaranteed to shut off.