GRADED CRUSHED AGGREGATE BASE COURSE FOR FLEXIBLE PAVEMENT

Has been made crushed aggregate base course project of an education center.

GRADED CRUSHED AGGREGATE BASE COURSE FOR FLEXIBLE PAVEMENT

REFERENCES

The publications listed below form a part of this specification to the extent referenced. The publications are referred to in the text by the basic designation only.

COMMISSION FOR THE STUDY OF ROADWAYS MATERIALS (CNR)

CNR Pamphlet No. 4 “Standards for coarse aggregates, fine aggregate, granular material, sand and additives for roadway construction”

AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM)

ASTM C 117 (1995) Materials Finer than 75-Micrometer (No. 200) Sieve in Mineral Aggregates by Washing.

ASTM C 136 (1996; Rev. A) Sieve Analysis of Fine and Coarse Aggregates.

ASTM D 1556 (1990; R 1996) Density and Unit Weight of Soil in Place by the Sand-Cone Method.

ASTM D 1557 (1991) Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft (2,700 kN-m/m)).

ASTM D 2922 (1996) Density of Soil and Soil-Aggregate in Place by Nuclear Methods (Shallow Depth).

ASTM D 4318 (1995; Rev. A) Liquid Limit, Plastic Limit, and Plasticity Index of Soils.

SUBMITTALS

Test Reports

Gradation

Bearing ratio

Liquid limit

Plasticity index

Percentage of wear

Density

Gradation

Smoothness

Thickness.

Samples shall be of the size and number required by the Contracting Officer and shall be furnished by the Contractor at no additional cost to the Government. Samples of the material shall be submitted for approval t least 30 days prior to starting the work. Samples of the material and grain size and specific gravity tests shall be submitted for approval at least 30 days prior to starting the work, and thereafter at regular intervals during production, as required by the Contracting Officer. These samples shall be obtained at the source, from trucks, stockpiles, or from other locations designated by the Contracting Officer. Samples for material gradation, specific gravity, liquid limit determination and plasticity index tests shall be taken as required. After the materials has been placed and compacted, samples for density tests shall be taken as specified in ASTM 1556 and additional samples for gradation, liquid limit and plasticity index tests shall be taken by an appropriate method.

Where deemed necessary, the sampling will be supervised by the Contracting Officer. All tests shall be performed by the Contractor at no cost to the Government. Results of all tests including copies of work sheets shall be submitted to the Contracting Officer.

DELIVERY AND STORAGE

Inspect materials delivered to site for damage and store as to prevent segregation and contamination.

WEATHER LIMITATIONS

Do not construct base course when atmospheric temperature is below 2 degrees C or when rainfall or other weather conditions detrimentally affect the quality of the finished course.

BASE COURSE

Aggregate for stabilized aggregate base course shall consist of crushed stone, crushed or natural gravel, angular sand, or crushed basalt. Materials shall be processed and blended if necessary to meet the gradation requirements. It shall be the responsibility of the Contractor to obtain materials that will meet the requirements specified herein and that can be constructed to meet the grade and smoothness requirements specified herein, after all compaction requirements have been completed. Aggregates shall be free from lumps and balls of clay, organic matter, objectionable coatings, and other foreign material and shall be durable and sound. The material retained on a 4.75 millimeter (No. 4) sieve shall be known as coarse aggregate, and the material passing the 4.75 millimeter (No. 4) sieve shall be known as binder material.

Coarse Aggregate

Coarse aggregate conforming to the requirements specified above shall have a percentage of wear not to exceed 50 percent after 500 revolutions. Coarse aggregate shall consist of fragments reasonably uniform in density and quality. Coarse aggregate shall be manufactured by crushing gravel or quarry rock, in accordance with CNR Pamphlet No.4, or shall be naturally occurring materials.

Binder Material

Shall consist of screenings of angular sand. Liquid limit and plasticity index requirements stated herein shall apply to any component that is blended to meet the required gradation and also shall apply to the completed course. The portion of any component or of the completed course passing the 0.425 millimeters (No. 40) sieve shall be either non-plastic or shall have a liquid limit not greater than 25 and a plasticity index not greater than 5 as determined by ASTM D 4318.

Gradation

Gradation requirements specified herein shall apply to the completed base course, and it shall be the responsibility of the Contractor to obtain materials that will meet the gradation requirements after mixing, placing, compacting, and other operations. The aggregates shall be continuously graded within the limits specified below: Sieve Size Percent by Weight Passing

50.0 mm 100

38.1 mm 70-100

25.0 mm 55-90

12.5 mm 35-70

4.75 mm 20-50

2.00 mm 12-35

0.425 mm 5-22

0.075 mm 0-10

The values are based on aggregates of uniform specific gravity, and the percentages passing the various sieves are subject to appropriate correction by the Contracting Officer when aggregates of varying specific gravities are used.

EQUIPMENT

All plant equipment, tools, and machines used in the performance of the work covered by this section shall be approved prior to commencement of work. This equipment shall be maintained in satisfactory working conditions at all times.

Aggregate Spreader

Shall be of the hopper type and shall be equipped with an adjustable screed capable of laying material to uniform thickness ranging from 2.5 to 20 centimeters or more over a minimum lane width of 2.45 meters. The hopper shall be a shape that minimizes segregation, and shall be carried on pneumatic-tired trucks or on drum-type steel rollers that will not dig into or scuff the subbase. The spreader may be either the towed type for attaching directly to the dump truck or the self-propelled type with sufficient power to propel the dump truck. An asphaltic-concrete paver may be used at the option of the Contractor.

Graders

Blade graders shall have a wheelbase of not less than 4.5 meters, a blade of not less than 3 meters in length, and shall be self-propelled.

Compaction Equipment

Steel-Wheeled Rollers

Shall be the self-propelled three-wheel type weighing not less than 9metric tons and shall have a minimum weight of 54 kilograms/centimeter width of rear wheel. The wheels shall be equipped with adjustable scrapers. The use of vibratory roller is optional.

Pneumatic-Tired Rollers

Light pneumatic-tired rollers shall consist of two axles on which are mounted not less than nine rubber-tired wheels, five wheels on one axle and four on the other, mounted in such a manner that the rear group of tires will not follow in the tracks of the forward group. The axles shall be mounted in a rigid frame provided with a loading platform or body suitable for ballast loading. The tires shall be uniformly inflated. The rollers shall be weighted as directed. The tractor or other towing equipment shall also be rubber-tired.

Tampers

Shall be of an approved mechanical type operated by either pneumatic pressure or internal combustion with sufficient weight and striking power to produce the required degree of compaction.

Vibratory Equipment

The use of plate vibratory equipment is optional and shall be as approved by the Contracting Officer.

Hauling Equipment

Shall consist of pneumatic-tired vehicles having dump bodies suitable for dumping materials without segregation.

Mixing Plants

If used, shall be so designed and constructed as to thoroughly mix the course aggregate, binder material, and water without excessive degradation of the aggregates.

Sprinkling Equipment

Shall consist of tank trucks, pressure distributors, or other equipment designed to apply controlled quantities of water uniformly over variable widths of surface.

Miscellaneous Equipment

Tractors, windrow equalizers, plows, and other equipment used on the job shall be of approved types suitable for constructing stabilized aggregate base course.

Gravel

Gravel fill shall conform to the gradation requirements for course aggregate used in the Aggregate Base Course as indicated in the paragraph “Base Course”

PREPARATION OF SUBBASE

Prior to constructing the stabilized-aggregate base course, the previously constructed subbase course shall be cleaned of all foreign substances. The surfaces of the subbase course will be inspected by the Contractor for the adequate compaction and surfaces tolerances. The subgrade shall conform to material indicated in Section 02315, “Excavation and Fill”. Soft yielding spots that may appear in the surface of the subgrade course, areas having inadequate compaction, and deviations of the surface from the requirements set forth therein shall be corrected to line and grade and to all specifications requirements. The finished surface of the underlying course shall not be disturbed by traffic or other operations and shall be maintained by the Contractor in a satisfactory condition until the base course is placed.

GRADE CONTROL

During construction, the lines and grades indicated for the stabilized aggregate base course shall be maintained by means of line and grade stakes placed by the Contractor at the site of the work.

CONSTRUCTION

General

The base course shall consist of aggregate processed, deposited, spread, and compacted on a prepared surface. The base course shall not be constructed when the atmospheric temperature is below 2 degrees Centigrade or when other weather conditions detrimentally affect the quality of the base course. It shall be the responsibility of the Contractor to protect all areas of completed base course against any detrimental effects. Areas that are damaged by freezing or other weather conditions, during any phase of the construction, shall be reconditioned, reshaped, and recompacted in conformance with the requirements of this specification without additional cost to the Government. Line and grade stakes shall be provided as necessary for control. Grade stakes shall be placed in lanes paralleling the centerline of the area to be paved, and suitably spaced for string lining.

Mixing of Materials

Coarse and fine aggregate shall be mixed in a stationary plant, or in a traveling plant. Coarse and fine aggregates shall be proportioned by weight or by volume in such quantities that specified gradation, liquid limit, and plasticity index requirements shall be met after the base course has been placed and compacted. Water measured by weight or by volume in quantities sufficient to provide the necessary moisture content for the specified compaction, shall be incorporated during the mixing operation. Mixing operations shall produce satisfactory uniform blending and the method of discharging into trucks shall not produce segregation.

Placing

Mixed material shall not be dumped in piles, but shall be placed on the prepared subbase in layers of uniform thickness with a spreader. No layer shall exceed 15 centimeters or be less than 8 centimeters when compacted. Layers shall be so placed that when compacted they will be true to grades or levels required with the least possible surface disturbance. Water content of the material shall be maintained during the placing period as required to obtain the compaction specified. Adjustment in placing procedures or equipment shall be made as required to obtain true grades, to minimize segregation and degradation, to reduce or increase water content, and to insure satisfactory construction.

COMPACTION

The stabilized aggregate base course in all areas shall be compacted with steel-wheeled rollers and rubber-tired rollers and/or other rollers, as approved. Water content shall be maintained at optimum or at the percentage specified during compaction. In all places not accessible to the rollers, the mixture shall be compacted with mechanical tampers. Compaction shall continue until the full depth is compacted to 95% of maximum density. The Contractor shall make such adjustments in rolling or finishing procedures as may be required for true grades, to minimize segregation and degradation, to reduce or accelerate loss or gain of water and to ensure satisfactory construction. Unsatisfactory materials shall be reworked to produce a satisfactory material. Degree of compaction required is expressed as a percentage of the maximum density obtained by the modified Proctor test as stated in ASTM D 1557. Compaction under Portland cement concrete pavements and bituminous concrete shall be 100 percent of ASTM D 1557. This will be abbreviated hereinafter as percent of maximum density.

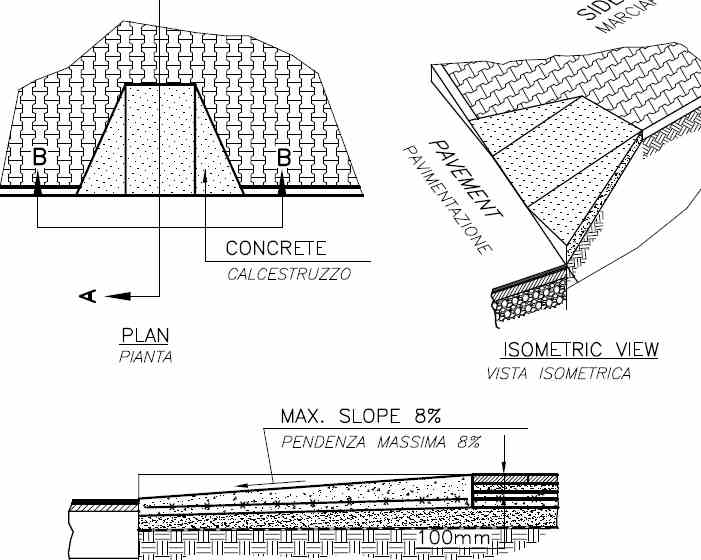

EDGES OF THE BASE COURSE

Without Side Forms

Approved materials shall be placed along the edges of the aggregate stabilized base course in such quantities as will compact to the thickness of the course being constructed, allowing at least 30

centimeters width of the shoulder to be rolled and compacted simultaneously with the rolling and compacting of the base course, as directed.

MAINTENANCE

After construction is completed, the course shall be maintained throughout except where portion of the succeeding course is under construction thereon. Maintenance shall include drainage, rolling, shaping, and watering as necessary to maintain the course in proper condition. Deficiencies in thickness, composition, construction, smoothness, or density, which develop during the maintenance, shall be corrected to conform to the requirements specified. Sufficient moisture shall be maintained at the surface to prevent a dusty condition by light sprinkling with water.

Before the application of the overlaying pavement, the underlying course shall be permitted to partially dry until the average moisture content of the full depth of the course is less than 80 percent of the optimum moisture of the material. The Contractor shall maintain the underlying course in a satisfactory condition until the overlying Portland cement concrete or bituminous concrete pavement, as applicable, is placed.

SAMPLING AND TESTING

Aggregates

Test each sample of base course material without delay. Make gradation tests from each sample in accordance with ASTM C 136. Make sieve analysis on material passing the 75 micrometers sieve in accordance with ASTM C 117.

Density Test

Density will be measured in the field in accordance with ASTM D 1556 orASTM D 2922. The maximum density at optimum moisture will be determined in the laboratory in accordance with ASTM D 1557 Modified, Method "C." A minimum of two field density tests shall be made within the limits of each 300 square meters of stabilized aggregate base course placed and compacted.

Smoothness Test

The surface of the underlying course shall not show any deviation in excess of 1 centimeter when tested with a 3 meter straightedge applied both parallel with and at right angles to the centerline of the paved area. Any deviation in excess of this amount shall be corrected by the Contractor by removing material and replacing with new material, or by reworking existing material and compacting, as directed.

Thickness Control

The completed thickness of the base course shall be not less than 1.5 centimeters plus or minus of the thickness indicated. The thickness shall be measured at intervals in such manner that there will be at least 3 thickness measurements for each 400 square meters. The thickness measurement shall be made by test holes at least 7.5 centimeters in diameter through the course. Where the measured thickness of the course is more than 1.5 centimeters deficient in thickness, the Contractor at no additional expense to the Government, shall correct such areas by scarifying, adding mixture of proper gradation, re-blading, and recompacting, as directed. Where the measured thickness of the base course is more than 1.5 centimeters thicker than indicated, it shall be considered as conforming with the specified thickness requirements plus 1.5 centimeters. The average job thickness shall be the average of the job measurements determined as specified above, but shall be within 1 centimeter of the thickness indicated.