Heating unit design

Our The design company has developed a psd of an individual heating system for the building of a hotel and business center .

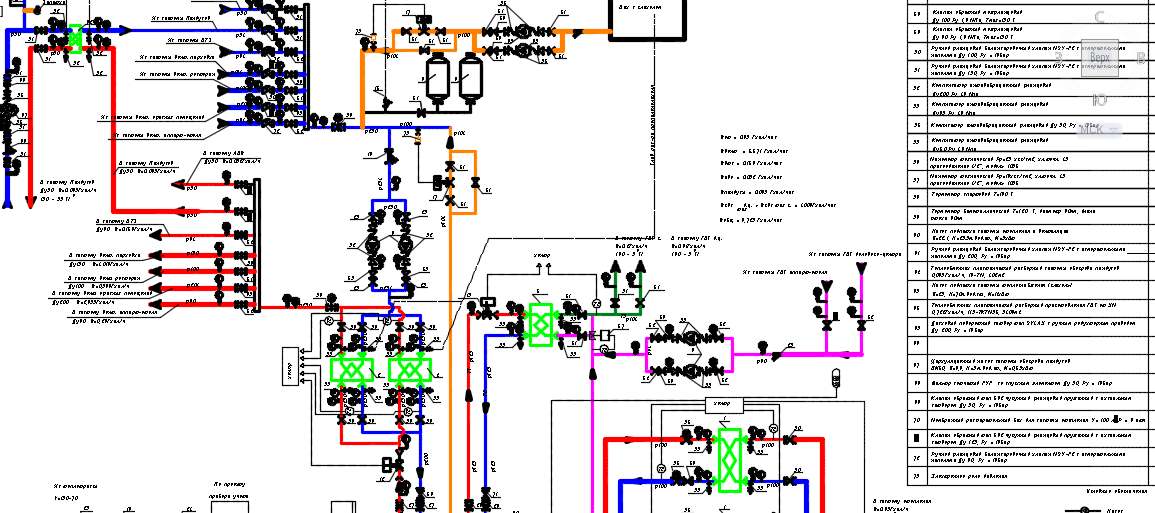

DESIGN OF THE central heating unit

The diameter of the pipeline input 2Æ250x4,5 is designed for the design load Q= 6.723 Gcal/hour. The input of the pipelines is carried out in the axes. Connection to the heating networks is carried out through an individual heat point (IPP), located at -4.250mm.

The primary coolant is heating water with a design temperature of T1 - T2 = 150 - 70°C (in the summer, the coolant temperature is T1 - T2 = 70 - 40°C). The individual heating unit is designed for connection to the heating networks of heating, ventilation and hot water supply systems of the projected "Hotel and business complex with underground parking.

The design is performed in compliance with the norms and requirements of SNiP 41-02-2003 "Heating networks".

CONNECTION DIAGRAM OF THE SYSTEMS. EQUIPMENT SELECTION.

Connection of the systems in the IHP is as follows:

-

Ventilation and heating - single-zone, according to the independent scheme (coolant - water-propylene 45% solution with a temperature of T12-T22 = 95 ° C - 70 ° C), 100% redundancy TS

-

heating - single-zone, according to an independent scheme (coolant - water with the temperature of T11-T21 = 85°С - 60°С), 100% heat supply redundancy

-

Hot water supply - single-zone, two-stage circuit (coolant - water with the temperature of T3 = 65 ºС). In addition, there is a TO for heat utilization from the refrigeration machine.

In the central heating unit provides for the installation of the following equipment:

- Heat exchangers for heating, ventilation and hot water supply systems - collapsible plate heat exchangers by "Ridan".

DESIGN HEAT LOADS, ETC.

Ventilation system:

- Heat supply of air inlets Qvent=4,471 Gcal/h;

- Thermal air curtains Qvtz=0,146 Gcal/h;

- Heating Qot=0,95 Gcal/h;

- Air-heating devices Qavo=0,052 Gcal/h;

- Heating of ramps Q ramps = 0,095 Gcal/h;

- DHW preparation Qgvs = 1,009 Gcal/h;

TOTAL: 6.723 Gcal/h

- Circulation pumps of heating systems are low-noise with a frequency converter of " Grundfos "TR 65-340/2- s series 2000 (1 - operating, 1 - standby), G =39,5 m3/hour, H=23 m.p.s, N =5,5 kW.

Calculation head of the network pumps:

Heating network H = Ht/Vt + NITP + Hsist = 0.18 + 0.2 + 1.90 = 2.28atm = 22.8 m.v.s.

- Circulation booster pumps of DHW systems are low-noise " Grundfos " brands TP 40-270/2 В (1 - operating, 1 - standby), G =8,32 m3/hour, H=21,1 m.p.s, N =1,5 kW operating in constant head mode.

Design head of circulation and booster pumps of DHW systems:

Ncirc. ГВС =Нфильтр+Нводомер+Нт/об +Нпотр.=0,1+0,02+0,07+1,8=1,99атм=19,9м.в.ст.

- Circulation pumps of heat supply systems with low-noise, frequency converter of " Grundfos TR 200-330/4" (1 - worker, 1 - standby), G =187,7 m3/hour, H=22,4 m.p.h, N =37,0 kW.

Network pump design head:

N network heating = Ht/Vt + NITP + Nsystem = 0.18 + 0.2 + 1.8 = 2.18 atm = 21.8 m.in.

- Make-up of the heating system is provided with network water from the return pipeline of the heating system. The height of the heating system (static):

Hst = 20.0 + 2.0 (reserve) = 22.0 m.v.s. ( 2.2 atm.

- Water make-up heating system (glycol circuit) is provided from the tank. Hst = 80m, G =25,3 m3/hour, N =11,0 kW. 2 pumps of "Grundfos" brand C RE 20-6 ƩN=11 kW.

The installation of the expansion tanks by "Reflex" - "G800" (heating system) and "G3500" (ventilation system) with two "Grundfos" pumps C R 15-3 ƩN=3 kW.

At the input of the heat network in the IHS, the installation of a metering unit for heat and coolant flow is provided, which includes:

- installation of a heat meter with two thermal sensors for metering the heat and flow rate of network water in the supply and return pipelines of the heating system;

- installation of water meter with a pulse output for metering water consumption in the make-up pipeline.

The supply pipeline of the heating system provides for installation of direct-action differential pressure regulators with adjustable setting "ART-86-125/16" by NPO Arkon for winter and summer modes of operation of the heating system. At the stage of RP the brand of the valve needs to be specified.

Installation of control valves with electric actuator "VB 2" of "Danfoss" company is envisaged. At the stage of RP the brand of the valve needs to be specified:

- at the supply pipeline of the heating system in front of the heating exchanger with Kv=40.0 m3/hour to regulate the water temperature in the heating system according to the outdoor air temperature. At the stage of RD the valve brand must be specified;

- at the supply pipeline of the heating system before the 2nd stage of the HHW exchanger - with Кv=40.0 m3/hour to maintain the water temperature in the system equal to 65 ºС and working in the cascade control mode. At the stage of RD the brand of the valve must be specified;

Magnetic filters are installed in front of heat meters, heat exchangers, water meters, pumps.

In accordance with the requirements of Section 10 of SP 41-10-95 "Design of heating substations" to reduce noise and vibration from the heating substation equipment in the project the following measures are provided:

- flexible vibration compensators are provided to connect the pipelines to the pumps;

- the pipelines are suspended with the help of clamps with vibration-insulating rubber gaskets;

- in places where the pipelines pass through building structures, the gap between the surfaces of the heat insulation structure of the pipelines and the building structure of the building is filled with vibration-isolating material.

The heating unit shall include:

- device of water outlet from the pipelines in the pit with pumping by a submersible pump into the sewage system (see section "AC");

- device of natural and forced ventilation (see the section "EIA").

The installation of the required number of measuring and control devices is provided for controlling the parameters of heat carriers in the IHS. Automation and dispatching of a separate project shall be developed.

FITTINGS. PIPE. INSULATION. BPE

Pipelines heating systems and systems "DH" designed from steel seamless hot-deformed steel GOST 8732-91, Art. 20 GOST 1050-88 *. Pipelines systems for hot water supply and water pipelines are designed from galvanized steel water and gas pipes GOST 3262-75*, Art. 20 GOST 1050-88*.

When laying pipelines in the IEP minimum slope is taken i = 0,003 in the direction of drain cocks Dy = 25 and 40mm. Emptying of equipment and pipelines is carried out through the drainage pipelines in the pit with subsequent collection of glycol in the tank. In the upper points of the pipelines shall be installed automatic high-speed air vent valves DU=20mm of the firm "Danfoss Danfoss ".

After completion of works, pipes and equipment are washed and tested with hydraulic pressure P=1,25õRrp, but not less than 10 kgf/cm2. Before carrying out insulation works, pipelines should be cleaned of dirt and rust and coated with silicone enamel KO-8174 two times. NT/Armaflex" insulation (tubes and sheets in rolls) with a thickness of d = 25 mm was adopted as insulation of pipelines. The covering layer is a self-adhesive multilayer material.

NOISE AND VIBRATION PROTECTION MEASURES

The heating and ventilation systems shall be designed taking into account the requirements of SP 51.13330.2011 "Noise Protection". Heating systems are provided with pipe fixtures with the use of rubber gaskets.

The velocity of flow of the coolant in the pipelines is taken no more than the values established by SNiP 41-01-2003 (2.04.05-91*). Pumps of heat supply systems are installed on foundations, for connection of pumps to pipelines flexible inserts (rubber compensators) are used. Pumps are equipped with frequency converter.

EQUIPMENT AND MATERIALS.

This stage of the Project provides for use of domestic and imported equipment and materials. All equipment and materials used for the complex construction are certified for use in the Russian Federation